+86-13914052243

With the development of the economy and the growth of social demand, there are more and more automotive connector mold parts with complex structures and special process requirements. Along with this, new mold materials with a high melting point, high hardness, high strength, and high toughness continue to emerge, and traditional machining can no longer meet the requirements.

Direct use of electrical energy, electrochemical energy, sound energy, etc., up to now, there have been a series of advanced equipment, which is widely used in various departments of automotive connector mold parts processing and customization. The EDM automotive connector mold parts is essentially different from mechanical processing. It does not require the tool material to be harder than the workpiece material, nor does it require significant mechanical force during the processing process, but directly uses electrical energy, chemical energy, and light. It can process the workpiece with sound energy to meet certain shape, size, and surface roughness requirements.

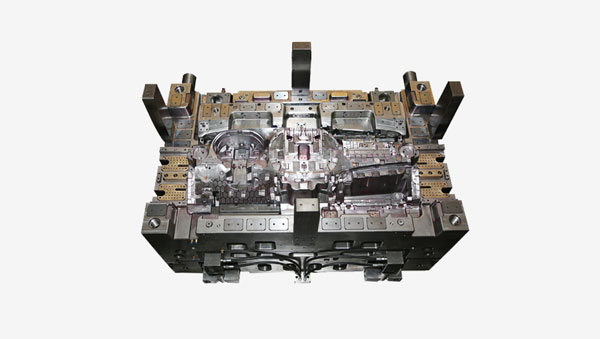

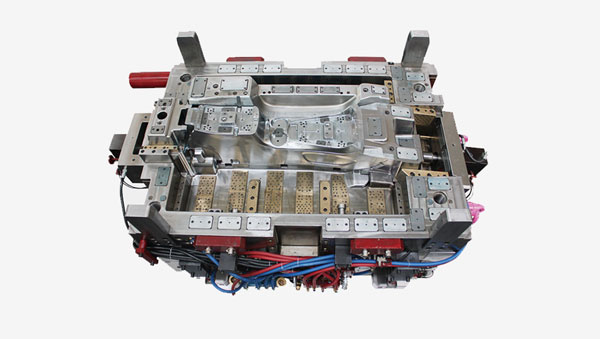

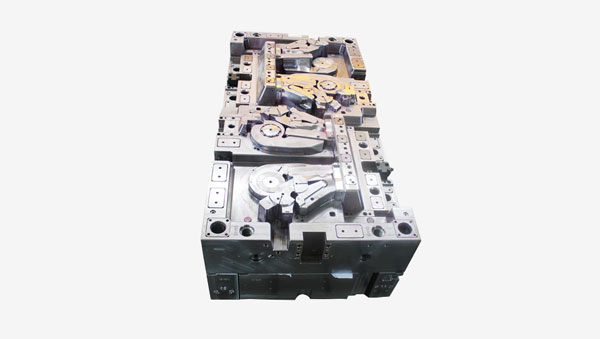

The EDM machine meaning is like electrical discharge machining or electro-erosion machining. It includes EDM forming, wire EDM, EDM inner hole, outer circle and forming grinding, EDM synchronous rotary machining, EDM surface strengthening, and lettering, etc. Process method. Commonly used in the processing and customization of automotive connector mold parts are EDM and wire EDM. At present, it is an important processing method for the surface of automotive connector mold parts. EDM machining refers to a process method to process the workpiece in a certain medium through the electro-corrosion effect of the pulse discharge between the tool electrode and the workpiece electrode. It can process a variety of materials with a high melting point, high hardness, high strength, high purity, and high toughness, and shows many advantages in production, so it is rapidly developed and widely used, to practice CNC die sinking and EDM fast hole drilling for instance. It is used for the processing of holes and cavities in the processing and customization of automotive connector mold parts of automotive EDM machine.

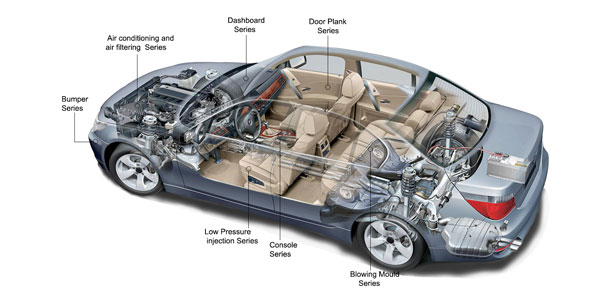

Bumper

The front and rear ends of the car are equipped with bumpers, which not only have decorative functions, but more importantly, have the functions of absorbing and mitigating external impact, protecting the body, and protecting the body and occupants. It can play a buffering role in the event of a low-speed collision. The front and rear car bodies can play a certain role in protecting pedestrians in the event of an accident with pedestrians. The front and rear bumpers of the car are converted from the precious metal materials to the current plastic materials, such as polyester, polypropylene, polycarbonate, etc., and are infiltrated into alloy components. They are made by injection molding, in addition to maintaining the original protection, in addition to functions, it can also achieve harmony and unity with the car body shape, making the car body more lightweight. The processed bumper not only has high strength and rigidity, but also has the advantage of being weldable, and has good coating performance.

Dashboard

The instrument panel is located directly in front of the driver, and it is generally equipped with a driving odometer, a speedometer, an engine tachometer, a fuel gauge, and a warning light. The instrument panel is divided into the non-airbag instrument panel and airbag instrument panel (more secure) according to safety and divided into the rigid plastic instrument panel, blister instrument panel, and semi-rigid foam soft instrument panel according to comfort. The hard-plastic instrument panel is made by the injection molding process, with a simple process, low investment, and wide application. Part or all of it is painted with decorative paint or soft-touch paint to improve appearance, color tone, or texture. The blister instrument panel is adsorbed and bonded outside the injection molding or pressing frame, or compounded with the skin during injection molding so that its appearance is cortical. The semi-rigid foam soft instrument panel is filled with polyurethane foam between the skin and the frame, which not only improves the touch but also increases the ability to absorb energy. At present, the skins of semi-rigid foam soft instrument panels mainly include vacuum thermoformed skins and slush-molded skins. The former is made by traditional artificial skin technology, and the latter is characterized by uniform patterns, no internal stress, wide design, and high tolerance. widely used.

Vice Dashboard

The car's auxiliary instrument panel (also known as the central channel) is a mechanism used to control gear shifts and place teacups and other objects, located in the middle of the cab. Different cars have different configurations of the sub-instrument panel, and the same cars have different configurations based on high and low grades. The sub-instrument panel is an interior part. Among automotive interior parts, it is an interior part whose complexity is second only to that of the instrument panel. The appearance requirements are high, and the surface needs to be textured. The auxiliary instrument panel is composed of the main body, the upper panel, the armrest assembly, the rear panel, the handbrake trim (skin), the gear trim, etc. It has front and rear ashtrays, cup holders, backup power supplies, rear air outlets, air ducts, and air conditioning Valve,s and other functions. In Japanese vehicles, the sub-instrument panel body is divided into two parts (the main body and the side panels), and the sub-instrument panel body in American vehicles is integral. At present, the auxiliary instrument panel is made of new plastic material injection molding

Car Door

The car door provides a passage for the driver and passengers to enter and exit the vehicle, and isolates interference from outside the vehicle, to a certain extent, to reduce side impacts and protect the occupants. The beauty of a car is also related to the shape of the door. The quality of the door is mainly reflected in the anti-collision performance of the door, the sealing performance of the door, the convenience of opening and closing the door, and the indicators of other functions. Anti-collision performance is particularly important, because when a vehicle has a side collision, the buffer distance is short, and it is easy to injure the people in the vehicle. To reduce the overall weight of the vehicle, the door is made of new plastic materials by injection molding.

Air Conditioning and the Filter

The car air conditioner shell (body) is an important part of the car. The structure of the air conditioner shell determines the performance of the air conditioner. It includes an air inlet and multiple air outlets. It can cool, heat, and heat the air in the car. Ventilation and air purification. Since the car is a relatively confined space, the unsmooth air for a long time will make us feel fatigued. This is also a problem for the driver. It is difficult to drive well, and it will be serious. There are certain hidden safety hazards, so now the air-conditioning device has become one of the signs to measure whether the car is fully functional, and it is made of new engineering plastic materials by injection molding.

Notes for maintenance of EDM small hole drilling machine

Notes for maintenance of EDM small hole drilling machine

The 2016 National EDM Machining Technology Seminar was successfully held in Beijing

The 2016 National EDM Machining Technology Seminar was successfully held in Beijing

N85 5-axis Simultaneous Control Cnc Die Sinking Edm Machine Has Been Added Into “qualified Suppliers Catalog Of Domestic Made High Rank Cnc Machine Tools For Military Industry”

N85 5-axis Simultaneous Control Cnc Die Sinking Edm Machine Has Been Added Into “qualified Suppliers Catalog Of Domestic Made High Rank Cnc Machine Tools For Military Industry”