+86-13914052243

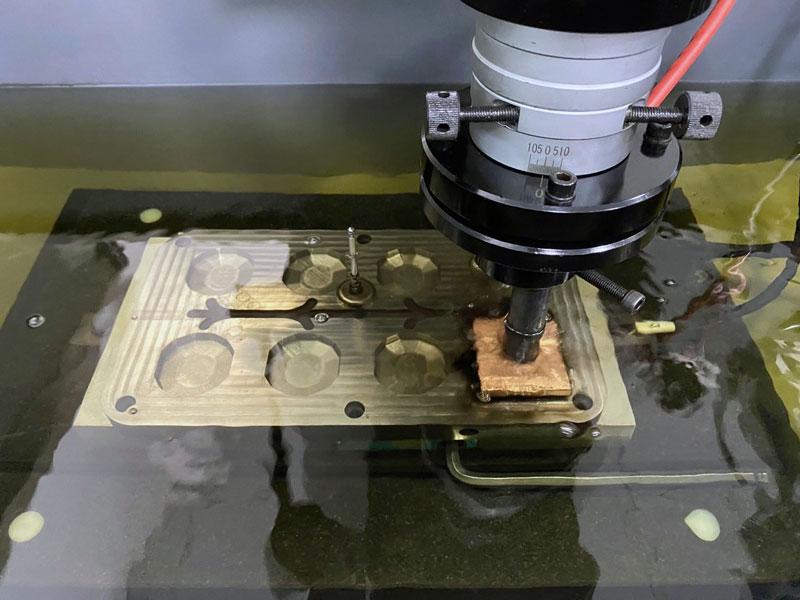

(1) Using the traditional method of "electrode touching the workpiece for centering", because the centering is a surface contact, many factors between the electrode and the workpiece will affect the accuracy of the centering-it is advised to use the reference ball for centering.

Fix a reference ball on the working table as the reference, please make sure the reference is clean. Before processing, install a reference ball in the spindle head to center the workpiece and then center the reference ball on the working table so that a distance relationship is obtained. Then for all electrodes, we do centering according to the reference ball.

(2) The accuracy of the reference surface of the electrode and the workpiece is not good, and there is debris, to ensure the accuracy of the reference surface of the electrode and the workpiece, make sure all reference surfaces are cleaned up.

(3) The sensing speed of die sinker EDM machine should not be too fast.

(4) Use precise clamping and positioning system, such as a clamping system from System 3R.

(1) The electrode material is not good, there are impurities, use high-purity copper.

(2) Improper selection of orbital cutting mode. Select proper orbital cutting profile according to the shape of the electrode and use fixed time machining for finish machining.

(3) Unsuitable EDM oil, such as EDM oil with high viscosity. Change suitable EDM oil for good surface finish discharging.

(4) Parameters need to be optimized-----appropriately decrease the discharging ON time, increase the pulse gap Off time, and reduce the servo reference.

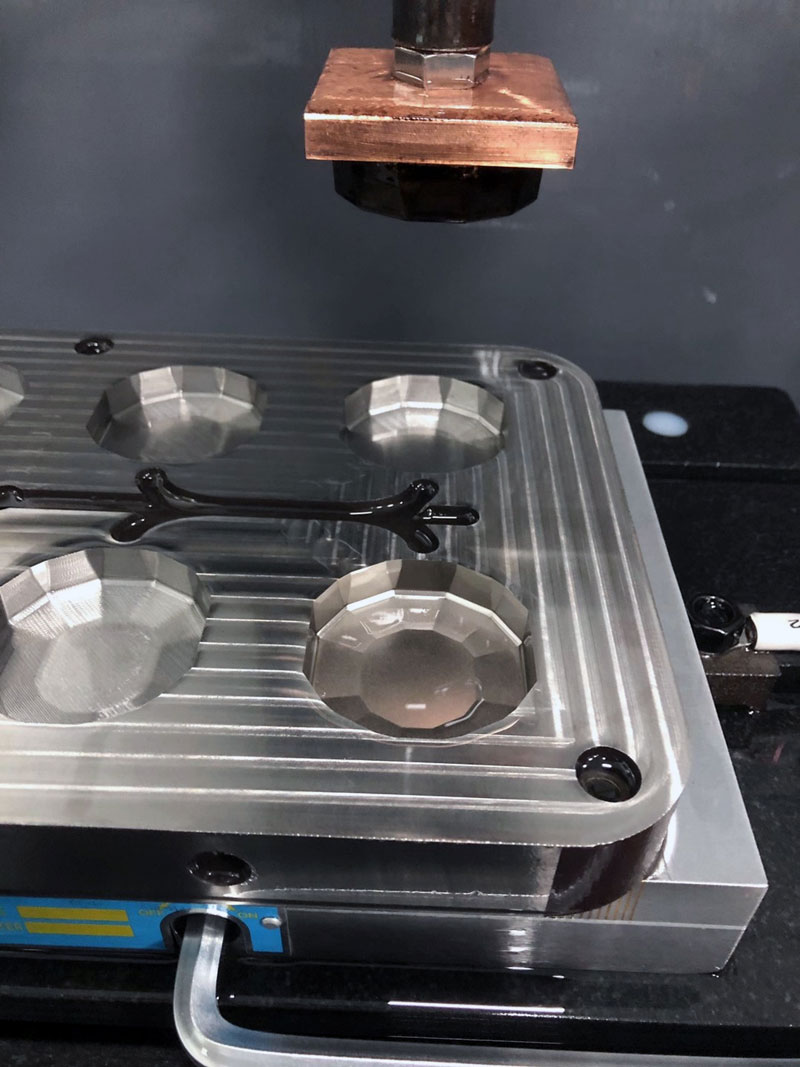

(5) Flushing method used-submerge cooling is recommended.

(6) Priority-The surface effect of standard priority is generally better than that of low wear priority.

(1) Some materials cannot achieve the mirror finish result, such as SKD11, Cr12MoV, DC53 (most metal stampings die steels) - It is recommended to use steel that can get mirror surface finish, such as SKD61, S136, 718HH, NAK80, etc., or correct the understanding deviation. For the mirror, surface finish CNC EDM machines, not mirror surface finish can be achieved on any kind of material.

(2) The machining area of CNC EDM die sinking is too big to achieve a good mirror surface finish result-the area greater than the diameter 60mm circle is not easy to get good mirror surface finish, customer can think about super finish surface and then do simple polishing to get mirror surface finish.

(3) Improper selection of orbital cutting mode- select the suitable orbital profile and use fixed-time machining for better mirror surface finish result.

(4) The input of the machining projective area is not reasonable input a more accurate discharging area so that the system can automatically generate a suitable machining program.

(5) Mirror surface finish machining conditions segments-according to the discharging status, adjust the height of the tool lifting, the discharging ON time, and the speed of the electrode lifting to match it. Do not use flushing coolant, use the submerged type.

(6) At the beginning of machining, the discharging is unstable and the electrode is frequently lifting.

(7) The impact of automatic detection and adaptive adjustment of the system-----turn off some automatic protection functions in the machining condition program, reduce the detection sensitivity, or set the control settings of the discharge time and the height of the electrode. It is set according to the user's setting (User/Fix) so that the electrode lifting is in a regular and controllable state.

(8) Optimize discharging parameters-----optimize the discharge ON time, lifting height, lifting speed, pulse gap, servo reference and etc.

Contact us to get professional application support.