+86-13914052243

The mirror spark machine itself needs high precision, so the installation accuracy and positioning accuracy of the electrode and the workpiece of the mirror spark machine are very important. But in some cases, the accuracy of the mirror CNC spark machine will be affected.

The temperature changes around the machine and the heat generated during electrical discharge machining are all factors that cannot be ignored. Because the main engine and most of the parts of the spark machine are made of metal, and the metal will expand and contract with temperature changes, which will affect the mirror spark machine. Therefore, how to maintain the accuracy of the mirror spark machine is particularly important. Here are four suggestions to help you maintain the accuracy of the mirror spark machine.

How to ensure the accuracy of the mirror spark machine for a long time?

① Do not point the mirror spark machine tools directly at the air vent of the air conditioner, and do not allow direct sunlight to hit it. Therefore you need to adjust the air conditioning equipment.

② The electrode used for processing will expand and contract with temperature changes. After rough machining, the electrode is heated in a stretched state. In order to minimize the impact, it is necessary to improve the cooling effect of the electrode and increase the processing liquid level so that the electrode is completely immersed in the processing liquid.

③ Install the machining fluid cooling device for the mirror spark machine.

④ After the rough machining of the mirror spark machine is completed, pause the machining and allow time for the electrode to cool down.

Protecting the accuracy of the mirror spark machine is a long-term work, so pay more attention to the above four aspects.

DMNC CNC

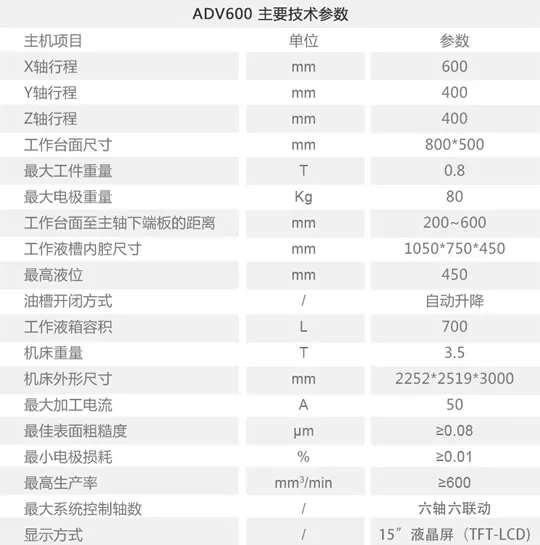

ADV series-ADV600

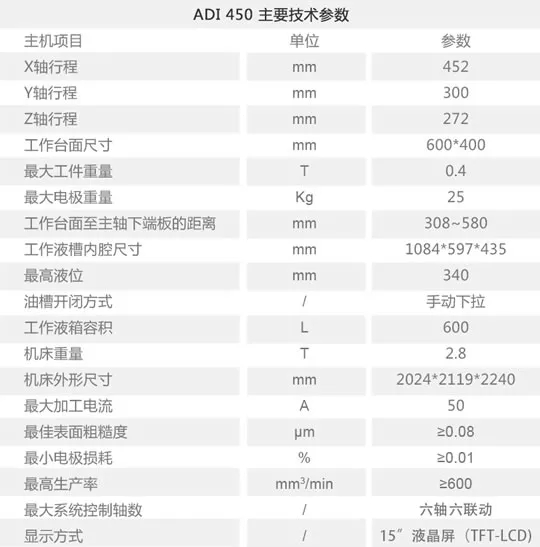

ADI series-ADI450

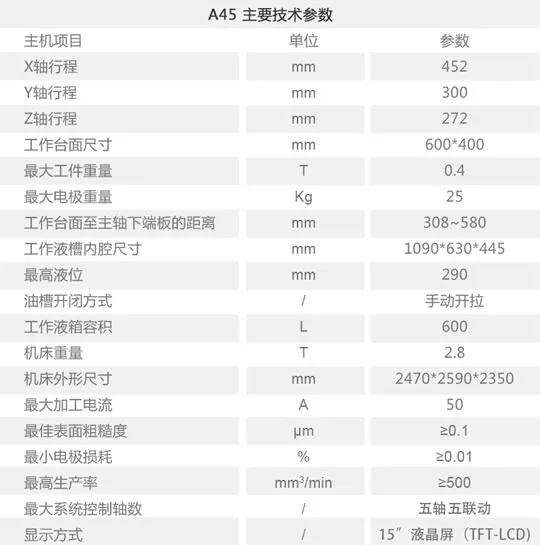

A series-A45