+86-13914052243

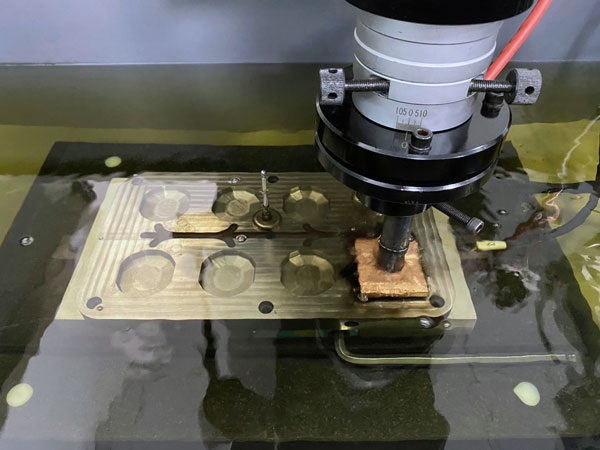

The basic principle of a CNC mould and die making machine is to erode the workpiece material through high temperatures generated by high-frequency power.

① The selection range of mold materials is wide, and the related requirements for electrode materials are relatively low. EDM machine uses the heat generated by high-frequency pulse discharge to melt the workpiece. There is no significant mechanical cutting force between the tool electrode and the workpiece, and it can process anything, hard, brittle, tough, and conductive material with a high melting point.

② EDM machines can also be combined with other machining methods at will, using their respective advantages to form new process methods and expand the processing range. Based on these advantages of CNC EDM die sinking machine, with the advancement of future technology, its application range is expected to be further expanded.

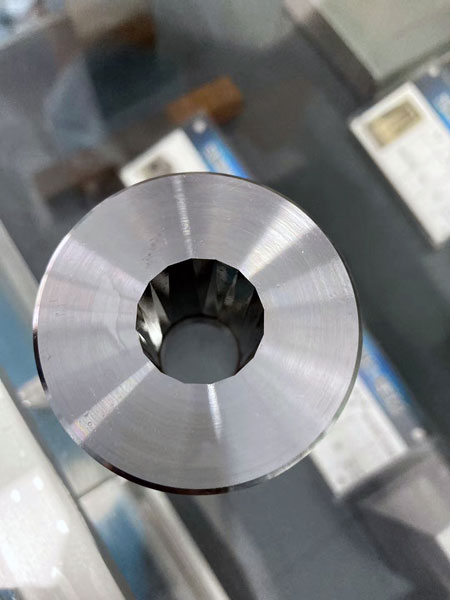

③ The workpiece processed by the EDM machine has high machining accuracy and surface quality. The pulse discharge time of the pulse power used in EDM is short, and the heat generated by pulse discharge is too late to diffuse to the surroundings, making the heat-affected zone of the workpiece material small; in addition, the pulse parameters of EDM can be within a larger range The adjustment can be carried out on the same machine tool in multiple modes such as rough, semi-rough, semi-precision, fine, and superfine machining.

④ Easy to realize automated production. Because it uses electric energy for processing, it makes full use of modern computer control technology to digitally control the power supply system of the wire EDM machine, thereby realizing automated production and computer intelligent production. Intelligence can reduce labor costs and improve efficiency.

① Stamping die, part of the CNC mould and die making machine, is the most widely used type of die in industrial production. Its concave die is difficult to obtain high machining accuracy by adopting traditional machining methods, and it is often scrapped due to quenching deformation or cracking during heat treatment. EDM machining, such as sinker EDM and wire-cut EDM, is used for machining such kind of molds widely, since EDM does not limit the hardness of the workpiece material, the template should be quenched as soon as possible. When the template is deformed, start processing the concave mold to avoid deformation caused by heat treatment as much as possible. And the template can be made into a whole without inlay fight, this not only simplifies the mold structure but also improves the strength and life of the mold.

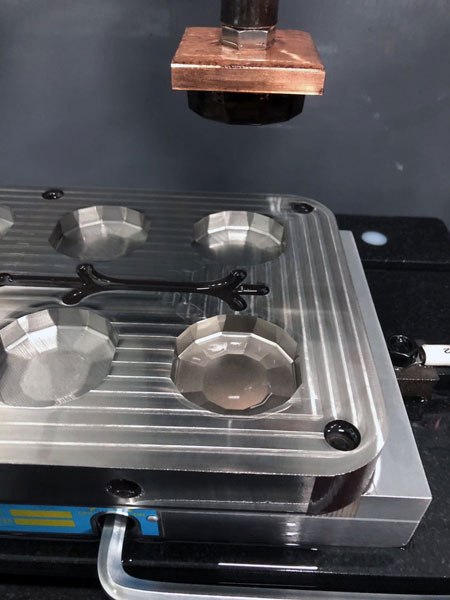

② For injection molds and die-casting molds, there are many small structures and reinforcing ribs after mechanical milling cavities or cores, which are difficult to machine with ordinary tools. Even if some parts of the milling can be machined with traditional machining methods, the accuracy of the machining cannot be guaranteed. With the development of science and technology, multi-axis linkage of electric spark machine tools more and more widely used, for the processing of fine micro-components, work parts inverted parts of the processing, the use of CNC multi-axis linkage electric spark machining processing to solve the problem that the traditional process can not solve.

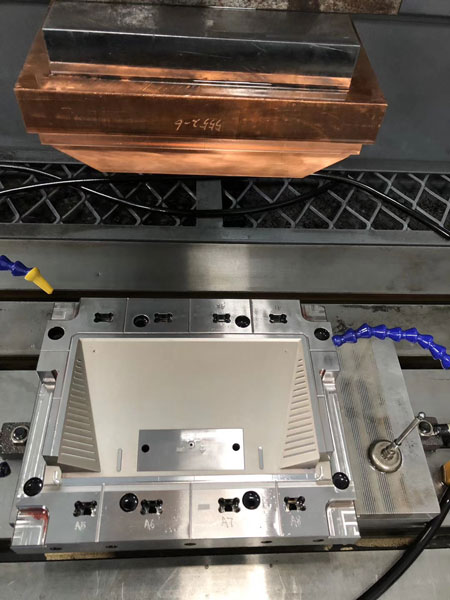

③ In the process of large-scale mold machining, usually use electric discharging machining as a follow-up processing of the milling, the positions that cannot be machined to the needed dimensions, the advantages of EDM machine can realize the finish machining.

④ Mirror surface finish processing. Today's for the surface of plastic decorative parts, there are many requirements for mirror surface finish, such as automotive exterior parts, notebook shell, etc., in order to achieve such kind surface quality, the production of these products of the mold cavity surface needs to be polished like a mirror, the traditional mirror surface finish usually achieved by artificial polishing, it is labor-consuming, and the requirements of polishing technician are very high, the use of high accuracy CNC die-sinking EDM machining technology can directly achieve the mirror surface finish in a small area.

⑤ With modern technology and the improvement of people's quality of life, today, many products are decorated with a bright appearance. Such as mobile phones, cameras, household appliances, etc. When producing the mold cavities for such products, high-performance CNC Electric Discharge Machines are used, which can achieve an even surface finish of the cavity under the premise of ensuring the accuracy of the mold size, so that the molded product surface forms a super fine finish.

Notes for maintenance of EDM small hole drilling machine

Notes for maintenance of EDM small hole drilling machine

The 2016 National EDM Machining Technology Seminar was successfully held in Beijing

The 2016 National EDM Machining Technology Seminar was successfully held in Beijing

N85 5-axis Simultaneous Control Cnc Die Sinking Edm Machine Has Been Added Into “qualified Suppliers Catalog Of Domestic Made High Rank Cnc Machine Tools For Military Industry”

N85 5-axis Simultaneous Control Cnc Die Sinking Edm Machine Has Been Added Into “qualified Suppliers Catalog Of Domestic Made High Rank Cnc Machine Tools For Military Industry”