+86-13914052243

(1) The initial electrical discharge machining efficiency is low-the electrode size scaling (spark gap) must be large, and the automatic programming can select the condition number of a larger current. The cavity should be pre-milled as much as possible.

(2) The last few segments of the program have low discharging efficiency-use the fixed time discharging function to effectively control the time of finish machining (the discharging time needs to be preset).

(3) The machining area that input when created the machining program is too small-the CNC EDM control system uses the area as the reference for discharging programming. Even if the electrode size is scaled up, the area is too small, and it will not create large discharge conditions. In such kind cases, you can increase the machining area value manually.

(4) The application type is not the correct-for example, the "standard" application type of small area machining is selected for the actual machining of a large cavity. Among all application types, "micro-machining" has the lowest efficiency.

(5) Machining priority-Selecting low-wear priority means low efficiency while selecting high-efficiency priority means faster speed and bigger wear of electrode.

(6) Unreasonable combination of discharging and electrode lifting-according to the discharging status, adjust the height of electrode lifting to match discharge time properly.

(7) Optimize the parameters of CNC EDM die sinker-reduce the pulse interval, increase the servo reference.

(8) Improved the machining technology-the use of graphite electrodes greatly improves overall production efficiency.

(1) Improper use of discharging parameters-the processing parameters with the priority of low wear should be used. Small electrodes can be selected for micro-machining application types.

(2) The discharging power is too big. For small and sharp electrodes, big current machining cannot be used.

(3) The discharging power is too small, and the machining efficiency is low, which cause that the discharging time is too long and wear of the electrode. If the electrode wear is too big and the machining speed is too slow, please adjust the parameters to increase the machining efficiency.

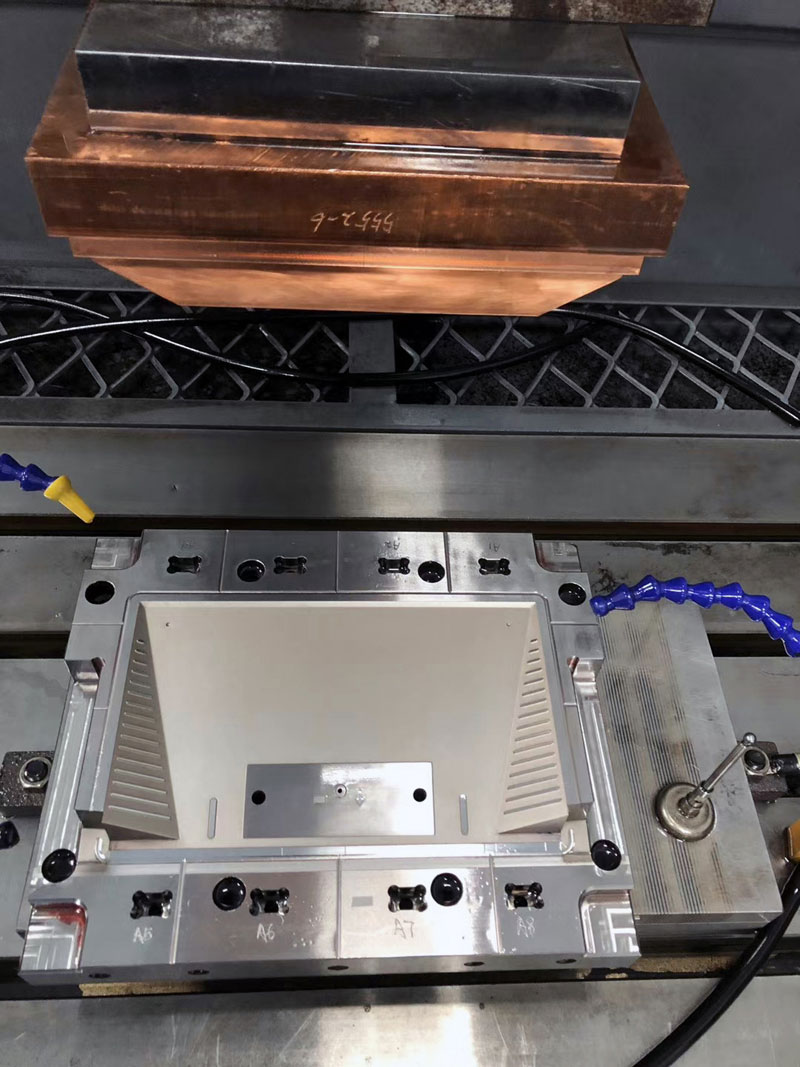

(4) The electrode material is not good-use high-purity copper or copper-tungsten alloy with lower wear as the electrode material.

(5) The pulse width is too small-increase the pulse width to decrease the electrode wear.